Water Movement In The Loach Aquarium

Water Movement in The Loach Aquarium

By: Martin Thoene with contributions by Tristan (crazyloaches) and killforfood.

This article does not seek to recommend any particular manufacturer's products over another, but rather provide a broad overview of the types of powerhead available and how the basic design and normal useage needs certain rethinking when used in aquariums housing loaches.

Why do our fish need water movement?

![]()

In my article Oxygen In The Aquarium, I have explained the physiological reasons that the fish we love require high levels of water oxygenation and also relish water movement of various strengths within their aquarium homes. Water movement is an intrinsic part of their natural habitat, so we must try to provide sufficient current (based on the species being kept) that best replicates the natural environment.

How may we provide that water movement?

We are lucky that the aquarium hobby is one of continuous, if sometimes slow development of technologies that help us provide ever more suitable environments for the long term healthy care of our pet fish.

Whereas years ago almost all water movement was created by using air as a motive force, since the early 1970's electric water pumps of various designs have been designed which increase the efficiency and adaptability of water movement. This article tries as best it can to show the basic differences in designs of in-tank water-pumping devices. We cannot show every type and model of pump because there are just too many manufacturers and models within their ranges, but we will endeavour to give a broad overview of the types of pumps available.

|

Packaging for Hagen Aquaclear 70 powerhead, formerly known as the 802. |

The need for this article arose because of repetetive questions that arise upon the Loach Forum regarding pumping devices and I have tried to include answers wherever possible to the sort of questions that get asked.

Here at Loaches Online, our truly international membership includes some highly innovative people and we tend to use aquarium equipment in slightly unorthodox ways that may never have been envisaged by the original designer. The natural inquisitiveness of some of us has led to various modifications being made to existing designs in order to have them perform better in some way in the challenging environment that may be experienced in a loach aquarium.

Needless to say, while these modifications have often proven to improve performance and be reliable in use, they most probably will automatically invalidate any manufacturer's guarantee or warranty, so this must be remembered before following any suggestions made here.

What is a Powerhead?

A powerhead is the generic name given to most water pumps intended for internal aquarium use.

Under-gravel filters were very popular at one time and really one of the first utilizations of biological fitration within home aquaria. They consisted of an under-gravel perforated plate and air-powered uplifts to suck water out from under the plate and thereby pull new water from the aquarium through the gravel substrate where millions of beneficial bacteria would live. In the interests of more flow capacity the development of small electrical powered water pumps allowed a design where a pump was placed on the top of the uplift tube near the water level. This provided power and sat at the head of the pipe, hence the term power-head.

These pumps were gradually produced by more and more manufacturers but the vast number of them are still being produced by Italian manufacturers. Other countries produce various similar products.

Generally, most of these designs consist of a magnetic driven impeller that is of a very basic paddle wheel design and ejects water under pressure from the impeller chamber by centrifugal force. The clearances within the impeller chamber are huge in engineering terms so most of these design pumps are not terribly efficient. However they are in most cases very reliable and will give years of good service with good maintenance if certain factors are taken into consideration.

The impellers usually spin on a ceramic or metal shaft and the magnetic drive portion of the assembly has a relatively small clearance with the housing it rotates within. Because most loaches prefer a sand substrate and indeed here at loaches Online we positively encourage fish-keepers to keep their fish over a sand substrate, ingestion of sand particles must be avoided. It can lead to seizure or at the very least premature wear of the shaft or the magnet housing. The magnet spins in a plastic molding which effectively isolates the electrical part of the motor from the water. If sand should grind through this plastic it can lead to electrical leakage into the water with the obvious associated dangers.

Using conventional powerheads in Loach Aquaria.

Because Loaches are primarily bottom-living fish we want to get the current provided by water pumps operating at a fairly low level in the aquarium.

Water movement will also be provided from the filtration used for the aquarium. I do not wish to go into details of filtration within this article as it is a subject within itself, however the way we use conventional powerheads in Loach aquaria and protect them from sand ingestion, invariably means they form part of a supplementary form of filtration.

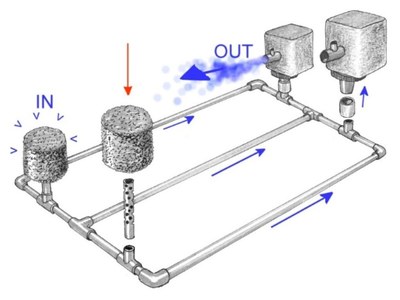

Back in 1998, in an effort to provide as natural as possible conditions for Hillstream Loaches in particular, I developed the River-Tank manifold concept. This concept has been modified and augmented by many people across the world of fish-keeping and now gets used in various guises for keeping all sorts of current-loving fish, not just Loaches. The powerheads are mounted at low level and intake sponges reduce the possibilities of abrasives ingestion whilst also providing a source of mechanical and biological filtration. In lightly bioloaded aquaria they could even be utilized as the sole source of filtration.

|

For details of this concept and the construction of a manifold look HERE. |

Using powerheads as additional current to augment filtration.

Powerheads may be mounted in various ways depending on the manufacturer's mounting options or by DIY ingenuity. As we usually mount them relatively low, protecting them from solids ingestion is important.

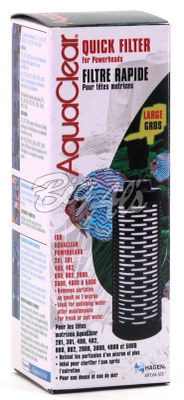

Various manufacturers produce what are generally called "Quick filters". These are fixed to the powerhead intake and consist of a perforated plastic housing that can be loaded with various types of filtration media. Usually a sponge or nylon floss is used. This protects the internals of the pump and traps solids plus providing an additional area of filtration media for colonization by beneficial bacteria.

|

Hagen Quickfilter that fits most Aquaclear powerheads. |

Alternatively, a sponge intended for an internal filter may be adapted to fit over the intake. Taking such precautions ensures that dangerous abrasive items like sand may be kept from the impeller and also prevents small fish or plant debris from entering the impeller chamber.

Choosing conventional powerheads.

All powerhead manufacturers produce a range of pumps that have different performance levels. We can choose which power level suits a given application based on species being kept and size of aquarium. Some manufacturers have pumps with classifications based on recommended usage in a given sized aquarium. Aquaclear for instance now categorize their pumps in tank capacity (US gallons) recommended sizings.

These are generally approximate values for average community aquarium type setups and with most Loach species we are often looking for higher rates of water movement than in the average aquarium. Therefore, we are often looking at a bigger sized pump than might normally be used. Some of the serpentine Loaches such as Kuhlis and Dojo Loaches (Weather Loach) do not like vast amounts of current but most other Loach species do and therefore we need to ensure our aquariums have suitably sized pumps to provide these conditions.

How much current do I need to supply?

This depends on what species you are keeping. It is best to initially look at providing suitable filtration to ensure clean water with minimal Nitrates. We often recommend using two or more filters so that maintenance to one has minimal effect on the biological filtration efficiency.

In a lightly loaded tank for Kuhli Loaches you would be providing excellent conditions with just a small hang on the back (HOB) filter that turned over the total capacity of the tank about 8 times an hour. No extra powerhead is really required because these fish live on the edges of relatively slow flowing waters in nature.

With something like Dojo Loaches the fish will produce far more solid waste due to their larger size and big appetites so a greater capacity is required. Using one big filter may create more actual current than the fish are happy with so it's often better to use two smaller filters that will turn over the tank's water a minimum of 10 times an hour. A small powerhead could be used to give increased surface movement and increase oxygen exchange while avoiding too much in-tank current.

Once we start looking at keeping Botiid type loaches the requirements jump up a notch. These are lively fish with big appetites and can produce a fair amount of biological detritus that needs processing by filtration. They have large requirements for clean and well oxygenated water. Here, we start to get into the realm of requiring cannister type filters. As I stated before this technology requires a dedicated article so I will just say that one should be looking at filtration that can turn over the tank capacity at least 12 times or more per hour. I try to set my tanks for these fish up with a primarily one way current so intakes and outlets are at different ends of the tank. In addition, extra powerheads are provided to up the total through-flow of water to around 20 times + per hour, including the filtration flow.

This sounds like a huge amount of water movement and when you do the math and work out what you'll need in pumps and filters to achieve that you will start to realize that setting up such an aquarium is a fairly expensive proposition. That's why I always advise people to first see what capacity they need then go comparison shopping via internet searches and find the best bang for your buck. Prices of equipment can vary drastically from manufacturer and manufacturer and also from different suppliers. If you find a killer deal but aren't sure about the actual pump's reputation you can always come and ask on the LOL Forums.

With River-Tanks for Hillstream Loaches I have generally found the magic minimum figure for the actual manifold itself is a turnover of at least 16 times per hour. Regard this as a minimum and size pumps accordingly. Also, when choosing pumps look closely at intake sizes with a view to the ease of adaptability to the actual manifold. For a very lightly loaded tank if you have reasonably large intake sponges you can use those as the sole filtration, but I like to have additional filtration by HOBs or cannisters to give a total turnover rate of at least 20 times per hour. This will be great for Schistura and other Brook type Loaches but with the sucker-bodied Hillstreams there's almost no limit to how much current they will enjoy. With all Loaches remember to design in areas in the tank decor that will allow fish the choice of resting out of the current.

Modifying conventional powerheads.

As stated earlier most paddle wheel type impeller design powerheads have various design inefficiencies. Some hobbyists have looked at these designs and experimented with modifying them to improve water flow.

Remember....as stated above....kiss your warranty goodbye once you modify anything from the manufacturer's specifications, but these mods do work.

LOL member killforfood is an innovative guy and looked at the Aquaclear 70 (formerly 802). I'm including his whole post on the subject and his pictures as they provide excellent illustration plus show his little tweaks to my basic River-Tank manifold design. Also, they show how he incorporated extra filtration into the system.

killforfood:

I’ve only been a member of LOL for a short time but reading the threads and articles about the River Tank began to appeal to my tinkering DIY mentality and I knew I had to build one. The theme that seemed to repeat itself in the information I read was the importance of achieving maximum water flow and not to skimp on the output of the power heads.

I began assembling parts and before long had everything assembled for a test run.

|

I used Beckett pond pump prefilter. |

|

The beautiful thing about AquaClear power filters is that intake tube is a perfect fit into standard ¾” PVC pipe making it easy to plumb into the manifold for added directional flow. |

|

I had an old Otto power head and bought a new AquaClear to go with it. |

|

Here’s the setup ready to fill and test. |

I filled the tank and plugged in the pumps and was immediately impressed with the output from the old Otto pump unfortunately I was very unimpressed with the comparatively anemic output from the new AquaClear.

To be fair, the Otto is rated at 500 GPH vs. the AquaClears 400 GPH.

|

After a quick inspection I realized the majority of the problem was the intake grate was blocking approximately 70% of the intake flow area. |

|

I also noted that the plate designed to control flow levels was a major restriction to the impeller even when in the full open position. |

|

So far everything appeared to be an easy fix but a test rig was in order to prove out the success or failures of my ideas. I came up with a simple idea to do a timed draining of a five gallon bucket. To start with I timed the pump with no modifications. It was a fairly anemic 96 seconds. That comes out be 187.5 GPH. |

|

First on the agenda was to remove that ugly grill. Time to pump 5 gallons, 78 seconds! 230 GPH. Thats an improvment but we can do better. |

|

Next, remove the flow adjuster plate. |

|

Increase size of opening on inner housing to give a straight shot at the impeller. |

|

With outer housing replaced, you can see here that the water has a clear shot at the impeller now. Time to pump 5 gallons, 68 seconds!! 264 GPH. I didn't do the math but thats a healthy improvement and the best part is that its free! Now I know some of you are saying “hey, were still way under the 400 rated GPH” but keep in mind that the copper drain tubing slips inside the output orifice and causes a slight restriction. Also note that as the bucket drains down there is over a foot of head to overcome not to mention three 90 degree bends in the copper tubing. Wthout the tubing and just shooting it over the side of the bucket I was able to empty the bucket in about 50 seconds. Thats 360 GPH and now almost feels as strong as the Otto! |

|

To really see the dramatic increase check out this side by side comparison of one that’s modified and one straight out of the box. You can see the close one puts up a little arc of water but the far one is splashing it clear up to the lights. |

Martin Thoene: I modified one in a similar fashion, plus I very slightly increased the diameter of the hole in the center of the red part and radiused it's intake side. I put a slight radius onto the inlet side of the outlet pipe to hopefully give a slight ease in flow out of the impeller housing.

I have added back in the yellow flow-adjuster part, but opened it up like killforfood did with the inner black housing. That gives a straight shot into the impeller, plus the yellow lever slot is covered properly. Left open, I reckon plant debris and stuff will get sucked in there.

Most noticeable difference is that it really buffets the hand when placed in front of it compared to the stock configuration.

Best flow (approximate) I got was 900 LPH which is WAY below the manufacturer's claimed 1540 LPH.

killforfood: I’ve found that a 1 ½” hole saw is the perfect size to increase flow to the impeller. It’s much faster than my pocket knife and makes a much more uniform hole size. For you folks across the pond, try a 40mm hole saw, its only slightly larger.

|

Modified flow adjuster plate. |

Hot Tip:

I also wanted to mention how I mate the powerheads to the ¾” manifold.

The funnel cones are too small to stretch over the ¾” PVC so I cut about a ½” off the small end and soak it in hot water to make stretching it over the PVC pipe easier.

|

Aquaclear adapters fitted to manifold parts. |

killforfood's modifications certainly make a big difference to the output of the Aquaclear 70 and it is likely that similar mods will work with other powerheads.

Sweeping powerheads.

![]()

One problem with the design of conventional powerheads is that the eject a very concentrated stream of pressurized water. this is not very natural considering that water moves as a large mass in nature. One attempt at spreading this output is made by the Zoo Med Power Sweep sweeping powerhead design. These were primarily designed for use in Reef tanks to simulate pulsing wave action but can be used in Freshwater applications for general current production. Their reported downfall in a marine application that gets mentioned frequently is a build up of calciferous algae which can gum up the sweeping nozzle mechanism. This should not be a problem in a freshwater application though.

|

Zoo Med Powersweep powerhead. This picture illustrates two items featured on many other powerhead designs. One is the rotatable flow direction deflector (at left) and the other is the venturi action air inlet (the pipe). Air is sucked into the adjustable air intake by the action of the water flowing through the pump's outlet nozzle and becomes diffused into the outlet stream. this provides some additional aeration. |

Impeller conversions.

As stated earlier the paddle type impeller has inherent inefficiencies and recently the advent of current producing pumps that use a design similar to a boat propeller has led one manufacturer to produce a conversion kit for a conventional powerhead design. This gives great current but precludes the use of the unit as anything other than a stand-alone current maker. In other words it cannot be adapted to any kind of manilfold piping or as an auxiliary filter.

The Sureflow1600 Conversion Kit is designed to work with the Maxijet 400, 600, 900 and 1200 conventional powerheads.

It replaces the paddle wheel type impeller with a boat type and encases it in a cage that allows water to flow in and out.

Tristan (crazyloaches) has supplied these excellent photos that clearly illustrate the conversion and show the design differences compared to a conventional powerhead.

|

Conventional Maxijet powerhead on left and the impeller and housing conversion kit of the Sureflow1600 |

|

Note marked difference between component designs. |

|

Note far larger blade size in the Sureflow impeller design. |

|

The Sureflow impeller is a direct replacement for the original. |

|

New housing fitted. Water enters via the large slots at the top of the housing and exits straight out of the bottom. |

|

Large water exit area. |

|

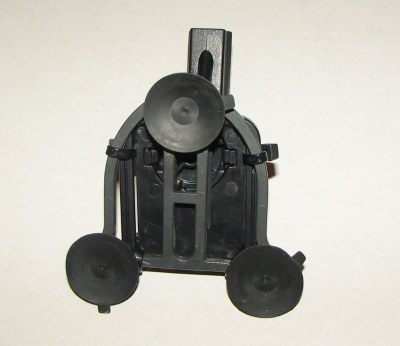

This is the mounting that comes with the sureflow kit. The instructions recommend Super-Glueing the components together. |

|

Note how Tristan used 4 cable ties to neatly secure the two components strongly together and allow separation if required in the future. |

|

The complete assembly ready to go in the aquarium. Effectively, this moves the orientation of the motor body through 90 degrees from it's original functional position but allows some directional aiming via the ball joint. |

A personal view of the Koralia water pump by Tristan (crazyloaches).

I happened upon these while searching for some good circulation pumps for my new tank I'll be setting up for my clowns and freshwater fish. I looked at many, Seio, Tunze, and others. But the Koralia caught my eye and was the most reasonably priced. The openeness of the pump was a concern; adventurous Botia might be able to actually get inside the unit. But I figured I could make a screen to go over it so I went ahead and got a pair of Koralia 4's. After having them in the tank today I figure I'd right up a brief review seeing how they haven’t been talked about much here.

One of the first things I noticed is the specs on the box are different than what’s on the literature inside. That makes me wonder about their quality but I'll give em the benefit of the doubt.

Technical Data from sheet:

1200gph 8.5W (115V 60Hz)

4600l/h 11W (230-240V 50Hz)

On the box it says:

1200gph 12W (115V 60Hz)

4600l/h 11W (230-240V 50Hz)

For what it's worth, other websites I have seen them advertised on have had even different specs, yet perhaps they have changed them once or twice and this is causing confusion, I don't know.

I took some pictures and compared it to the common Maxi-Jet, which I have several of. I used a MJ600 since I wasn’t using it, but the bigger MJ1200's also have the same identical housing. The MJ1200 is rated at 295gph and 20W.

|

Profile view. Maxijet 600 at left, Koralia 4 at right. |

|

Front (outlet) view. |

|

Disassembled view of motor, note that the Koralia motor housing is smaller than the Maxijet 600 in all dimensions. |

|

Maxijet mounting at left and two-part magnetic (through the glass) mounting for Koralia at right. |

|

Conventional "paddle wheel" design Maxijet impeller (left) and Koralia "propeller" (right). Note the permanent magnet is even smaller on the Koralia |

|

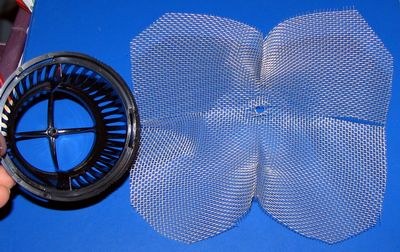

Koralia impeller housing disassembled. |

My first impressions were very good. The design is very similar to the Tunze Turbelle Nano Streams (just from what I have heard and see on the net - I don't have one). I think it was the model 6045 that most similarly matched the Koralia4. But it costs double. I purchased the K4 from Drs Foster & Smith for $48. Even in my 75G which I am testing one out now the flow isn’t too severe for my plants or blowing substrate away (but I am not going to leave it in there long term). The flow seems to spread out a great deal, but still pushes water for a good distance. At about 4" the flow is less forceful on my hand than my Maxi-Jet 1200, but I am sure the volume of water its moving is much greater. I am wondering why they haven’t really used propeller shaped pumps before... they seem ridiculously more efficient. Then I thought, well up until recently most 'power heads' were specifically designed to work with undergravel filter tubes and such, and thus needed an intake that could be hooked to a tube. Well this one is more like a boat, with water being drawn in freely from all around the propeller and pushed out into the open unrestricted. The main part of the pump is about the size of my fist and is slotted all over for the intake. Placing 1 or two finger across the intake I cannot feel any suction, it takes 3 or 4 fingers wide for me to feel some suction. It would take a lot for this to clog, which is one of the problems I run into with my Maxi-Jets and plants. Even on my 75G the K4 isn’t too powerful, but I don't know if I would put one on a tank much smaller.

Noise is uncertain. For some reason my canopy is resonating when closed. With the canopy open I really cannot hear the Koralia run over the gentle hum of two other powerheads and two Rena XP3 cannister filters below. In which case I would call it very quite for its flow. But when my hood is closed the pump makes a fairly loud hum. I'll call it an issue with my hood since when open the pump runs very quiet, and I'll try later to move the pump around and see if I can figure out why my canopy wants to amplify the hum.

The K4 is their biggest by the way, for smaller tanks they do make smaller pumps. These are intended for my 240G were I will have at least 2 of them for supplemental movement.

Seio Super Flow Pumps

Seio Superflow Pumps made by Taam Inc. have been around a while now and are another departure from conventional design. All models are very powerful with the top of the range producing up to a claimed 3000 US gallon/hr. They are relatively expensive but well-made and certainly provide excellent circulation without the concentrated blast of larger conventional designed powerheads.

I was looking for a big pump to provide good current in my 125 gallon Clown Loach tank and got one of those "too good to be true" deals on a Seio M1500 that I couldn't refuse because it was true! I was very impressed with the quality of the construction of these pumps. They come with a multitude of heavy-duty and neatly designed options for mounting and can be used in various ways. The design precludes using them as a conventional powerhead though.

Below is a build up from the basic components to illustrate the innovative design.

|

Here is the basic M1500 motor body. Water enters via the slots and the outer sleeve can be rotated to open or close the slots to adjust flow. |

|

Looking up the outlet you can see the quite thick ceramic impeller shaft. I have heard that people have fractured these when re-assembling their pumps after cleaning so you have to be careful. Ceramic shafts do seem to have low wear rates compared to steel shafts but you must still ensure that sand does not get injested as obviously this can seriously affect wear and tear. Note that the housing is quite markedly internally tapered in design. |

|

This is the unique shaped impeller used in these pumps. The taper conforms to that of the housing. I have found that plant debris can catch on the back (top as you look at it here) of the fins and restrict water flow or stop the impeller. |

|

With the impeller fitted into the motor body you can see that clearances are quite tight. |

|

This is the shaft support housing. It is sealed by an O-ring and is a push fit into the housing. You have to ensure the shaft is located into the rubber support bearing before pushing the housing home. |

|

To resist water pressure pushing the housing out this threaded ring holds it on. |

|

When screwed into position this is what it looks like. |

|

The rotatable outlet nozzle is a push fit onto the outlet. It tiurns the flow through 90 degrees and the inner part is adjustable to direct flow. |

|

Here it is fitted to the pump assembly. In this configuration the nozzle can be rotated through a very wide angle. If one of the other mounting methods was utilized a full 360 degree adjustability is available. On the top of the unit you can see a blue part. This is an air inlet and is adjustable. It allows air to be injected into the impeller housing to further increase aeration capability. A hose will need fitting to it if the top of the unit is submerged. |

|

This extra housing is used to further isolate fish from the concentrated suction at the intake slots. |

|

Fully assembled the pump is quite large. It's heavy too and requires the six large suckers to support the weight when used like this. |

|

Front view. The rectangular oultet provides a widespread exit for the water and prevents the concentration of pressure we find with conventional powerhead designs. |

|

In the aquarium the suction hanger allows mounting at any height. |

The Problems with Loaches

The Koralia pump, the Sureflow Conversion kit and the Seio Super Flow were primarily designed to answer the needs of Marine fishkeepers for diffused current producing pumps for Reef tanks. In that use there are certain issues that arise with long term use. These mainly relate to good regular maintenance procedures due to possible build ups of calciferous micro-organisms on components.

Freshwater aquarists must also ensure they do regular maintenance of the equipment and our biggest problem is often the ingestion of plant debris which can clog or stop a pump's operation. Conventional powerheads running via a Quickfilter or via a River-Tank manifold are isolated from direct problems associated with plant matter, but these more open use pumps are not.

Another problem stems from the fish we keep. Loaches tend to be inherantly inquisitive and will seek to investigate tight spaces. They also love to swim against currents and will often try to swim into a water outlet. Obviously, when we look at the designs of these pumps above we can see the inherent dangers in their designs for an overly inquisitive fish. Another problem is that most loaches and particularly sucker-bodied Hillstream Loaches like to graze over surfaces and in this case could be in danger from any high suction areas of the pump.

Tristan found that his Koralia pump had obvious problems with plant debris ingestion and he noted the ease with which an inquisitive Botiid nose could gain access to the spinning impeller. This is how he modified the pump.

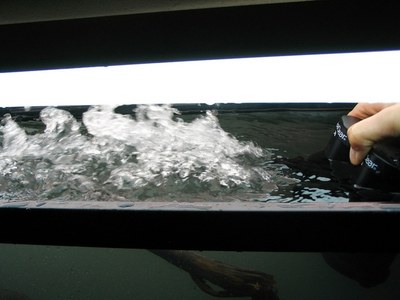

|

A mesh guard was made to completely surround the impeller. |

|

It was molded into shape to tightly conform to the inner part of the intake strainer. |

|

It looks really neat when assembled. |

|

In use in the aquarium it can clearly be seen how the mesh prevents ingestion of large particles of plant debris or tiny fish and how the central water outlet is also protected. A nosey Botia cannot get to the fast-spinning impeller with the obvious dire results that might entail. Tristan used this modified system for a while but found that the mesh is so fine that it would clog up with plant debris rather too quickly and needed frequent cleaning. This type of modification could also be carried out on the Sureflow conversion although possibly the mesh might have to be mounted externally which might not be as aesthetic. |

The Seio pump basically has a two stage debris strainer when fitted with the outer slotted box. It does however have a glaring design problem of concern to those keeping loaches.

|

This highly visible gap exists above the outlet nozzle and it is very easy for fish to slip through this and get closer to the higher suction at the inner intake slots. Regular fish are unlikely to get inside this outer defence but because Botiids and other loaches will orientate themselves at whatever angle is required to go where they wish it is very easy for smaller fish to get inside the box. I have watched my 2.5" Botia histrionica go up right inside this outer box and fiddle around inside the housing looking for bits of food and then quite happily exit again. Obviously, they have no problem with the internal part's suction but i an msure that really small fish might. I have not needed to isolate this danger because my fish are larger but I would think that a piece of coarse filter foam might be cut to conform to the inner wall of the strainer box and be glued inside to allow ease of slipping the unit onto the pump body but allow closure of the gap shown here. Assembling the pump without the outlet deflector fitted would allow one to trace the shape required. The likelihood of fish swimming up the outlet is low due to the strong flow but should that happen the design of the impeller precludes any likely damage to the fish as all is presented to the fish is a spinning reversed cone shape, no actual blades. |

With modified conventional powerheads such as the killforfood ones shown above removal of the intake strainer bars opens up the possibility of ingestion of solid matter that might have previously been caught. Snails are one of the biggest problems and I have experienced Malaysian Trumpet Snail babies working their way through the intake sponges on a River-Tank manifold and then getting sucked through to the pump strainer. Obviously, with this removed they can then get into the spinning impeller and might cause breakage of the impeller blades. Ensuring that snails are eliminated or the intake sponges regularly cleaned can prevent such problems.

Excessive Heat Production

![]()

Generally, the larger a pump is the higher wattage consumption and the greater the residual heat created. Depending on ambient air temperatures and other factors this heat production can be a problem. With fish such as Hillstream Loaches where required temperatures are generally lower and water movement much higher than in regular aquariums excessive heat buildup during the Summer months can be a real issue.

The most efficient tactic for combating heat is to blow air across the water surface via a small fan. This dissipates heat via evapouration but naturally leads to rapid water loss. This must be replaced via water changes NOT water top-ups otherwize dissolved solids may rise and hardness will increase.

![]()

Hopefully, this article has given you some insights into the use of powerheads within the Loach aquarium. These fish present certain issues to us that need consideration in order to prevent damage or death to the fish. Some Botiids can be hard on plants and create debris that can cause problems for the pumps, plus the use of much preferred sand creates its own issues that must be addressed. Our fish and the required equipment can be expensive so we must ensure that with suitable precautions we give each the prospect of long life.

Martin Thoene, with many thanks to Tristan (crazyloaches) and killforfood.

Document Actions